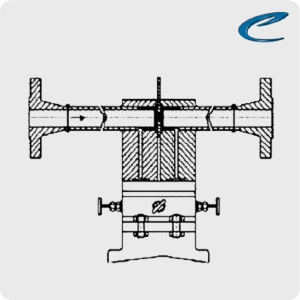

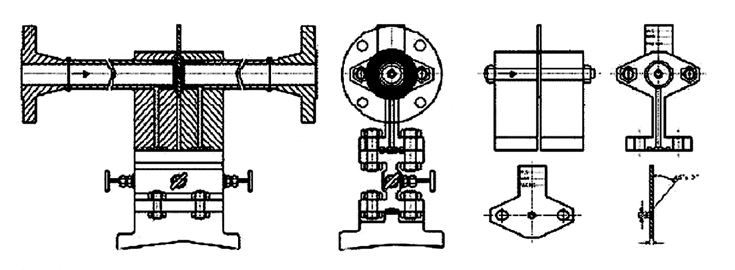

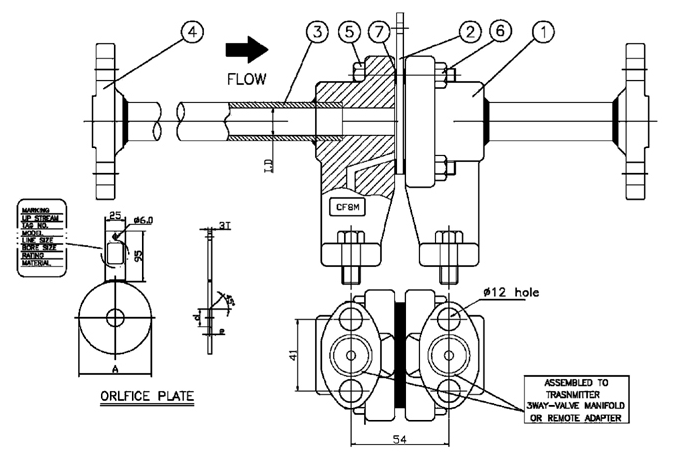

MODEL (HIO)

This is supplied with the meter tube and is designed for direct installation with DP Transmitter i.e., the Meter tube is an integral part of the secondary flow measuring device. The external tubing is eliminated here. These type of Meter Tubes are always provided with corner tappings and are largely recommended for gas flow measurement with smaller line sizes viz; 15 NB to 50 NB where DP is very low. The corner tappings are provided in the form of annular grooves so that, the purging of the fluid into the tap is very effective and reading of DP becomes easy.

Fluids

Liquids, gases and saturated steam

Materials

Orifice assembly, stem and manifold: 316LSS

Orifice Body: 304SS, 316SS, 316LSS

Process Connections

Wafer body to fit between the following flange drillings.

ASME B16.5 (ANSI) Class 150, 300, 600, 900, 1500#.

Line Sizes

15A, 25A, 40A, 50A, 80A, 100A, 150A, 200A

Temperature limited

Process: -40 to 121 °C (-4 to 250°F)

Arnbient: -40 to 70 °C (-4 to 158°F)

General

Gas flow measurements of very low DP smaller line sizes 0.5″ to 2″ where the tubing is difficult and DP reading becomes difficulting case of small DP which necessitates the use of DP transmitter integral with the meter. 3-way value manifolds are supplied with the assembly which are suitable for mounting the DP transmitter.